Your Position:

Index

>

Gelizi Stell Mill

Your Position:

Index

>

Gelizi Stell Mill

1779: Foundation of the factory.

1825: The construction of the steel blast furnace.

1915: Construction of a Siemens-Martin furnace work

1952︰ The first 50 ton electric arc furnace operating.

1954: Use the 60MN hydraulic press

1990:Start of Schmiedewerke Gröeditz Casting Co., Ltd.

2006:Establishing a representative office in China.

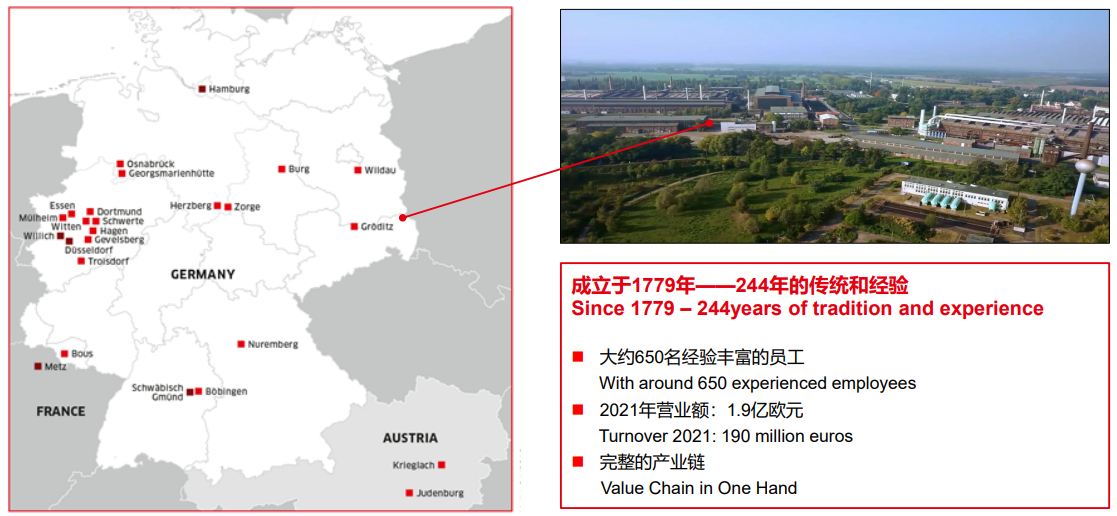

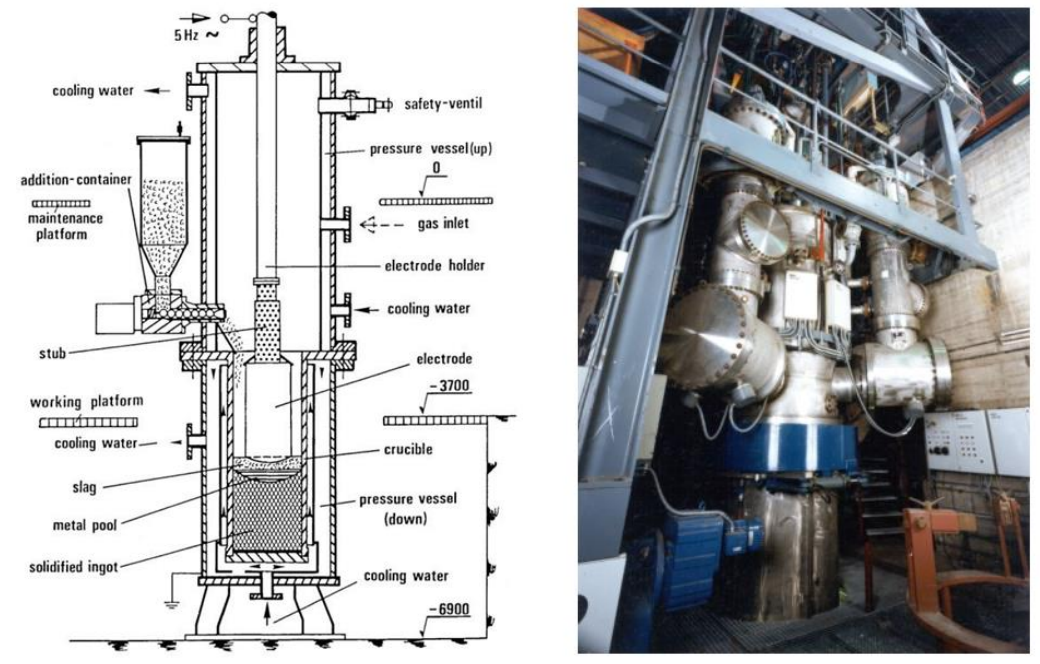

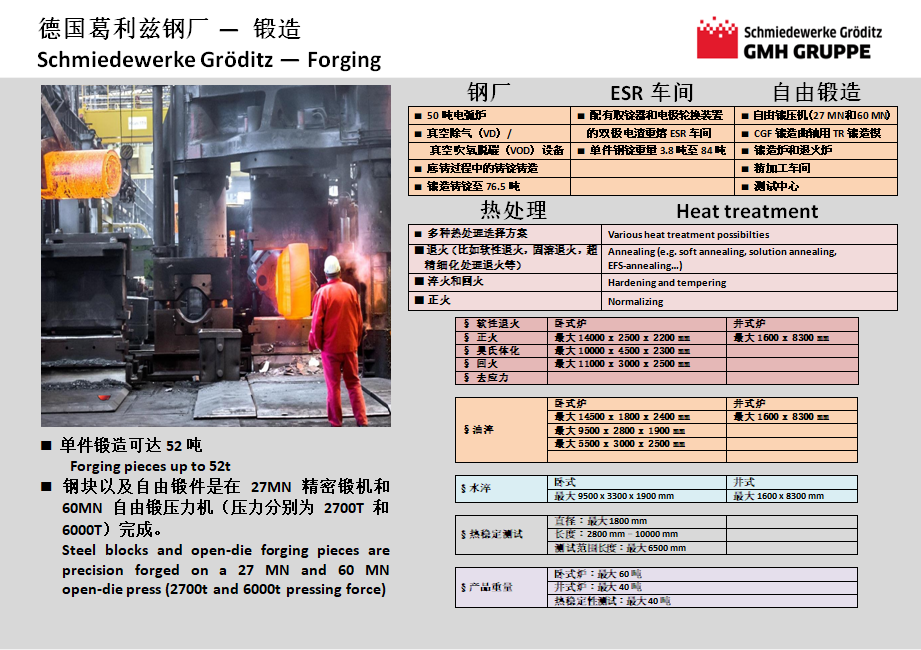

Founded in 1779, Schmiedewerke Gröeditz Steel Plant in Germany has been a renowned steel plant for over 240 years. With its extensive product portfolio, it provides the international market and industry with a solid foundation for progress. Approximately 300 steel grades and over 2000 derivative steel grades enable various industries to accurately find the steel they need. Schmiedewerke Gröeditz has excellent precision, dimensional accuracy, and special material properties, such as high purity, uniform microstructure, wear resistance, and corrosion resistance. In order to produce high-quality steel, Schmiedewerke Gröeditz Steel Plant has equipped ESR equipment that allows for a weight of 84 tons of large steel nails. In addition, the production process has been tested for a long time, and it has extremely high production efficiency.

The experts at Schmiedewerke Gröeditz always find the best solution for different customer needs: precisely and personalized customization according to product specifications and customer needs. The comprehensive chemical metallographic and mechanical testing methods that comply with international standards ensure stable and high-quality steel. Schmiedewerke Gröeditz quality system of the steel plant has passed ISO9001 certification, and the energy and environmental management system has passed ISO50001 and ISO14001 certification.

Energietechnik Essen— PESR-UNIT

With over 240 years of experience in producing high-quality mold steel, Schmiedewerke Gröeditz has a delicate quality assurance system, advanced equipment, and a dedicated business philosophy. It offers approximately 300 steel grades and over 2000 derivative steel grades, enabling customers from all walks of life to accurately find the steel they need.

Crafted with craftsmanship and striving for excellence, Schmiedewerke Gröeditz steel as excellent precision, dimensional accuracy, and special performance, such as high purity, uniform microstructure, good wear and corrosion resistance, and crack resistance.

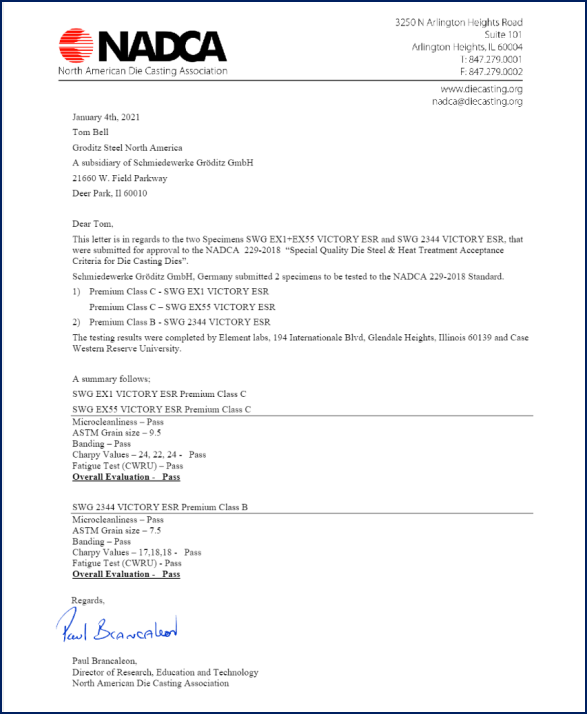

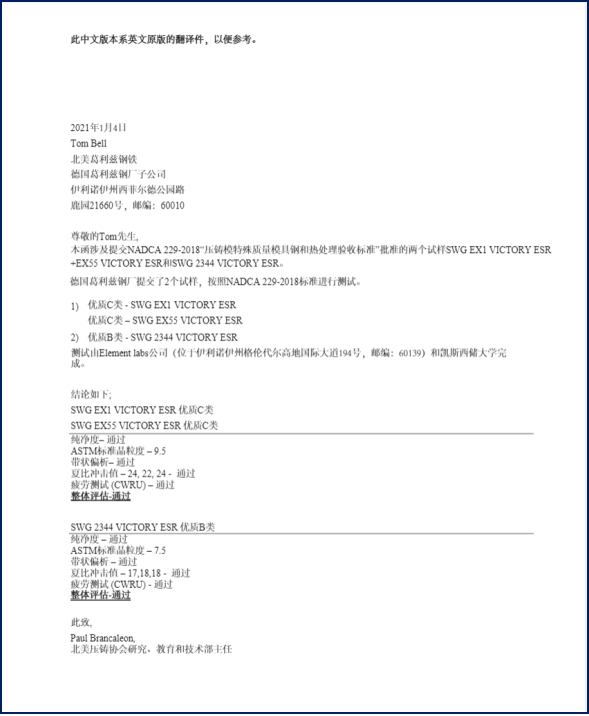

Schmiedewerke Gröeditz submitted 2 samples for testing in accordance with the NADCA229-2018 standard

SWG EX1 VICTORY ESR PREMIUM CLASS C

SWG EX55 VICTORY ESR PREMIUM CLASS C

SWG 2344 VICTORY ESR PREMIUM CLASS B

Micro cleanliness-Pass

ASTM Grain size-9.5

Banding-Pass

Charpy value-24,22,24- Pass

Fatigue(CWRU)- Pass

Overall evaluation-Pass

Micro cleanliness-Pass

ASTM Grain size-7.5

Banding-Pass

Charpy value-17,18,18- Pass

Fatigue(CWRU)- Pass

Overall evaluation-Pass

Address:

TEL:0755-28070708 Fax:0755-28070718